Department of Mining Engineering.

Portada » Gold Placers in Chile: Developing a New Protocol for Sustainable Development

Department of Mining Engineering

While copper remains the primary focus of Chile’s mining industry, other minerals are also extracted, albeit with varying levels of industrial development. Gold is one such mineral, and in regions like Magallanes, it is predominantly extracted from deposits known as “placers.” These placers consist of mineralized zones formed by sediments of varying grain sizes, typically loose gravel and sand, that contain gold fragments or nuggets deposited by rivers or other natural processes. The gold in these deposits originates, for example, from quartz veins containing gold. When these veins are exposed on the surface, they undergo weathering, erosion, transport, and sedimentation processes. Gold is commonly found in sediments along active riverbeds or streams, but it can also be located in ancient riverbeds or paleochannels. These paleochannels, often situated near the surface, are easier to identify and extract compared to other types of gold deposits. The extraction of gold from placers is relatively straightforward. At its simplest, it requires only a pan or “chaya,” into which raw material and water are added. When the mixture is shaken, lighter materials float to the surface and are discarded, while the denser gold settles at the bottom of the pan.

This simplicity has kept gold placer mining largely artisanal, requiring minimal technical planning or investment. However, this low level of development presents two significant challenges. First, miners often operate without long-term strategies for identifying resource-rich areas or estimating extraction potential, leading to job instability and inefficient resource utilization. Second, the lack of prior knowledge about gold locations results in widespread environmental disturbance, as miners disrupt areas that could have been exploited more sustainably.

Department of Mining Engineering

To address these challenges, a team of researchers from the UC School of Engineering, led by Professor Carlos Marquardt, developed a methodology to optimize the sustainable exploitation of gold placers. Their approach focuses on creating a “geo-mining-metallurgical” model during the early exploration stages, integrating geological, mining, and metallurgical data. This model was tested through a pilot project at a gold placer in Tierra del Fuego, located in the Cordón Baquedano Mining District, approximately 35 km from Porvenir in the Magallanes Region.

The process began with a series of drillings or wells to collect soil samples and analyze their gold concentration, measured in milligrams per cubic meter.

For each 2 x 2 meter well, surface vegetation was carefully removed, a 1.5-meter-deep hole was drilled, and soil samples were collected. After sampling, the vegetation was replanted to ensure minimal environmental impact. The data gathered from these wells served as the foundation for the geo-mining-metallurgical analysis, which was conducted in three stages:

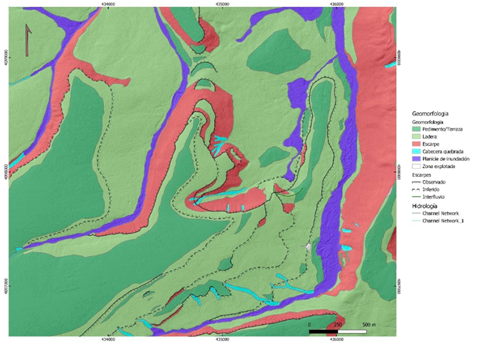

This stage involved creating detailed geological models through fieldwork and data collection. Researchers identified and described the types of rocks, sediments, and regoliths in the area. This information was combined with data from the exploration wells, including gold concentration, as well as geomorphological and topographical data obtained using drones. The drone imagery provided high-resolution details of geographic features and terrain variations. Based on this analysis, the study area was divided into distinct zones according to its composition and characteristics.

Ruins of the gold mining mills of the Cordón Baquedano, which were operational during the gold rush in the 1910s.

This stage focused on developing mathematical models to estimate gold distribution across different sectors by extrapolating data from the collected samples. The first model tested was the “Polygon Model,” a simple and widely used method in artisanal mining. In this approach, polygons are drawn around each sampling point, dividing the area into zones based on the samples collected. The gold concentration from each sample is then assigned to the entire polygon, assuming uniform mineral distribution within each zone. The second model, known as the “Inverse Distance” method, is more sophisticated. It calculates gold concentration at a specific point based on its distance from known values derived from samples. The closer the point is to the sample, the more similar its value will be. Lastly, the most complex model they analyzed is the “Kriging model.” Here, in addition to the factors considered in the previous models, the estimation error for each projection is also calculated.

After conducting these tests, the researchers concluded that the Inverse Distance and Kriging models are the most accurate and effective for planning the extraction process.

This last stage focuses on how to process the material to extract the gold. With this purpose, the researchers studied the raw characteristics of the materials, including sediment’s grain size, or “granulometry,” composition and geochemistry.

This research, led by Carlos Marquardt culminated in the development of the document “Exploration, Evaluation, and Geo-Mineral-Metallurgical Modeling Protocol for Gold Placers,” which is publicly available and primarily intended for small and medium-sized mining operations. Interested parties can request a copy by emailing mineriauc.ing@uc.cl.

Implementing this protocol could reduce extraction times by targeting areas with higher gold concentrations, thereby increasing the resources extracted and enhancing long-term projections. Moreover, this protocol could represent a step forward in the transition toward more sustainable mining practices.

Part of the sample processing mobile plant used in the field. On the right side of the image, the Trommel (blue), and to the right, the gravity concentrator (yellow).

Department of Mining Engineering

Part of the work team (from left to right: Carlos Marquardt, Felipe del Valle, and Tomás Roquer) along with the gold miner Jorge “Toto” Gesell Díaz, who has worked for decades in the Cordón Baquedano in Tierra del Fuego, Magallanes Region.