Department of Mechanical and Metallurgical Engineering

Portada » SHIPcal-CL: An Assessment Tool to Boost the Use of Solar Heat in Industry

Department of Mechanical and Metallurgical Engineering

Department of Mechanical and Metallurgical Engineering

Did you know that many industries require large amounts of heat to operate? From food, beverage, and plastics factories to chemical and paper plants, all of them need high temperatures to carry out their processes. In Chile, that heat is still generated mainly from fossil fuels, leading to significant environmental impacts and an unsustainable reliance on energy.

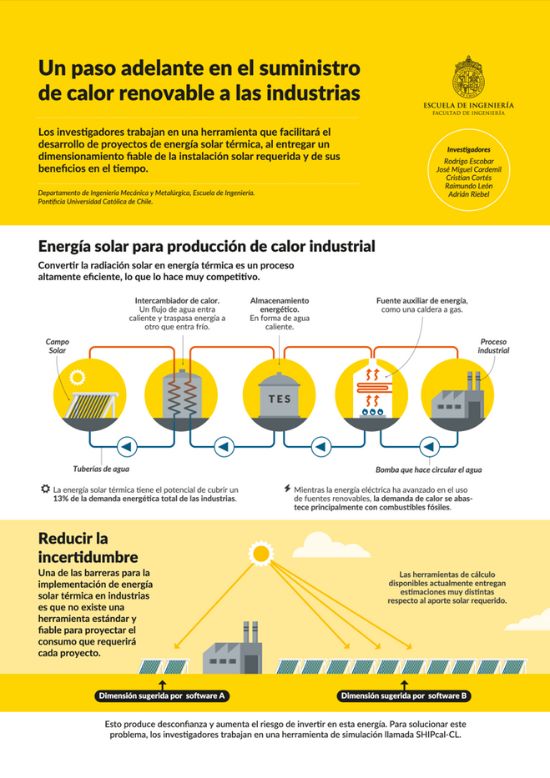

But there is an alternative: using the energy of the sun. Chile has one of the highest levels of solar radiation in the world, making it an ideal territory to harness this clean and renewable source. The technology to convert solar radiation into heat, known as “solar thermal energy,” is highly efficient and capable of reaching temperatures of up to 400°C and beyond, which makes it a very competitive option for providing heat to numerous industrial processes.

Despite its potential, the use of this technology by industry remains very limited both in Chile and around the world. The reason? Technical and financial uncertainty.

Solar thermal collectors that convert solar radiation into usable heat, offering a renewable alternative for heat supply across various sectors.

The obstacle: uncertainty and lack of tools

In the industrial sector, energy decisions require more than good intentions: they need reliable data, clear projections, and the assurance that the solution will work under the specific conditions of each plant. Without that foundation, any change is perceived as a risk.

For a company to confidently incorporate solar thermal energy, it must first address some basic yet critical questions. How much thermal energy does its operation require? At what times of day and during which seasons of the year? Is it possible to partially meet that demand with solar thermal energy, considering the available land area, process temperatures, and the plant’s geographic location? In addition, the total cost must be taken into account, not only the solar collectors and their installation, but also other components such as thermal storage and control systems, as well as ongoing costs like operation and maintenance. Finally, the associated benefits must be understood, both economic and environmental, which are determined by the energy contribution of the solar thermal system.

The tools currently available to evaluate solar thermal systems often deliver inconsistent results, as many do not take into account key variables such as hourly consumption profiles, thermal losses, stratification in storage tanks, or collector overheating, among others. This leads to unrealistic estimates of the solar energy contribution, which increases uncertainty. In addition, the lack of public data and analyses tailored to the reality of Chilean industry causes these projects to be perceived as risky and uncompetitive.

The Chilean Solution: SHIPcal-CL

To address this challenge, a team of Chilean researchers: Rodrigo Escobar, José Miguel Cardemil, Cristian Cortés, Raimundo León and Adrián Riebel are developing SHIPcal-CL, a free online platform specifically designed to facilitate the design, analysis, and techno-economic evaluation of solar thermal systems in industrial processes.

Unlike other available tools, SHIPcal-CL will use dynamic models that allow highly accurate simulation of the behavior of industrial solar thermal systems over time. This includes key aspects such as solar variability, thermal demand profiles, the behavior of stratified storage tanks, and steam purge mechanisms under collector overheating conditions. These elements, often omitted in commercial simulators, are essential to accurately represent the complexity of real solar thermal systems and to reduce uncertainty in the results.

SHIPcal-CL will provide users with a set of key decision-making indicators, including investment costs, expected annual savings, net present value (NPV), internal rate of return (IRR), levelized cost of heat (LCOH), emissions mitigation, and the energy contribution of the solar thermal system. These indicators are intended to help non-specialists in the energy field make decisions as informed as possible. In addition, more detailed results will be delivered on the operation and power output of the solar thermal system over a typical meteorological year, all within an intuitive web interface designed for people with varying levels of knowledge about solar energy.

The tool is being developed with an open-source philosophy, allowing both industry and academia to use, adapt, and improve its models without access barriers.

The tool is being developed with an open-source philosophy, allowing both industry and academia to use, adapt, and improve its models without access barriers.

Department of Mechanical and Metallurgical Engineering

The goal of the project is for SHIPcal-CL to become a national standard for the design of solar thermal solutions, helping more companies make informed and secure decisions. For this reason, the platform will be freely available on Exploradores, the digital platform of the Ministry of Energy. In addition, real data from the case study will be shared so that anyone can validate the results and compare them with other tools.

Thanks to its user-friendly design, technical robustness, and ability to adapt to different scenarios, SHIPcal-CL represents a concrete opportunity to drive the adoption of solar thermal energy in the country. In a country as rich in sunlight as Chile, harnessing solar energy should be seen not as a risky bet, but as an evidence-based opportunity.

A Tool to Accelerate the Energy Transition

Solar field that supplies heat to the swimming pool at the San Joaquín Campus of the Pontificia Universidad Católica de Chile, consisting of 56 m² of flat-plate collectors (FPC) and 105 m² of evacuated tube collectors (ETC).

To validate the results provided, the researchers will test the tool with a real case: the solar thermal system that heats the swimming pool at the San Joaquín campus of the Pontificia Universidad Católica de Chile. For this, the installation is being upgraded, including a new storage tank and a sensor system that will allow monitoring of the system’s operating variables.

Once the experimental system is in place, the details of the solar thermal setup will be entered into the tool, and the simulator’s outputs will be compared with the experimental data from the real installation. This will allow researchers to assess the reliability of the estimates provided by SHIPcal-CL.

This type of practical validation is key for building trust within the productive sector particularly among small and medium-sized enterprises, which often lack specialized technical teams and the flexibility to experiment with new technologies.

Testing in the field: from theory to practice

Department of Mechanical and Metallurgical Engineering