Department of Chemical Engineering and Bioprocesses

Department of Construction Engineering and Management

Portada » An Activated Carbon Tank for more Efficient and safe storage and Transport of Green Hydrogen

Department of Chemical Engineering and Bioprocesses

Department of Construction Engineering and Management, Department of Chemical Engineering and Bioprocesses

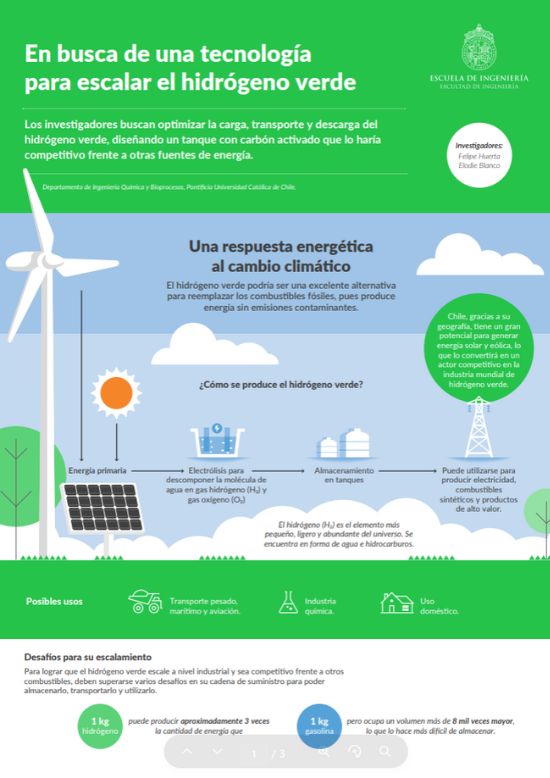

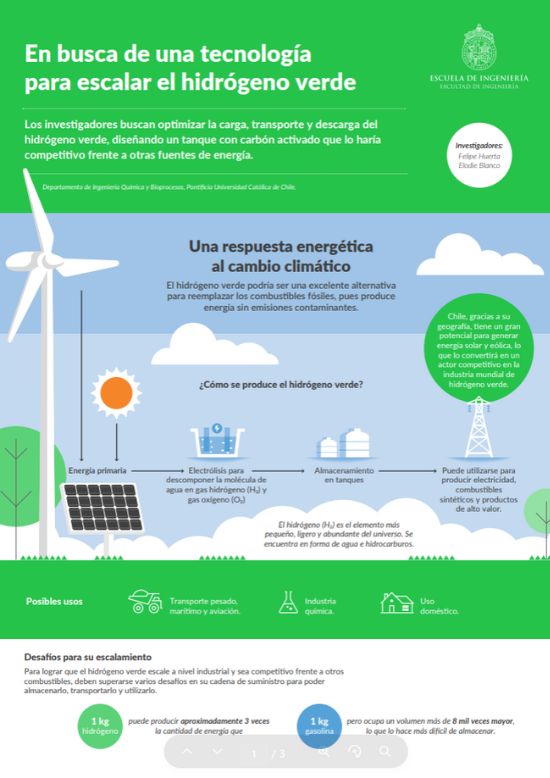

Green hydrogen is emerging as a powerful solution in the transition to cleaner energy. It provides a way to generate electricity without releasing harmful greenhouse gases. Unlike traditional fossil fuels, green hydrogen offers a cleaner alternative, helping reduce the environmental impact of energy production. The production of green hydrogen begins with electricity generated from renewable sources such as solar or wind power. This clean energy powers a process called electrolysis, which splits water (H₂O) into hydrogen (H₂) and oxygen (O₂) in their gaseous forms. The resulting hydrogen is then stored and transported for future use as a sustainable energy carrier.

Green hydrogen plays a crucial role in solving the intermittency issues of renewable energy. Solar and wind energy production is variable—solar power depends on sunlight, while wind power relies on wind speed. This means electricity production is not always stable. Hydrogen offers a solution: it can be converted into heat when used as a fuel or into electricity when used in fuel cells. These fuel cells work in reverse of electrolysis, generating electrical energy from hydrogen and oxygen.

Challenges in Storing and Transporting Green Hydrogen

Despite its immense potential, green hydrogen still faces significant hurdles, particularly in storage and transportation. While just one kilogram of hydrogen gas at atmospheric pressure can produce three times the energy of the same amount of gasoline, it occupies 8,000 times more volume. This presents a major challenge in making hydrogen practical for widespread use. Currently, this challenge is primarily addressed through the use of pressurized tanks. However, hydrogen’s small molecular size presents technical difficulties in keeping it securely contained. Specialized hydrogen storage tanks have been developed, but their high costs make large-scale adoption difficult.

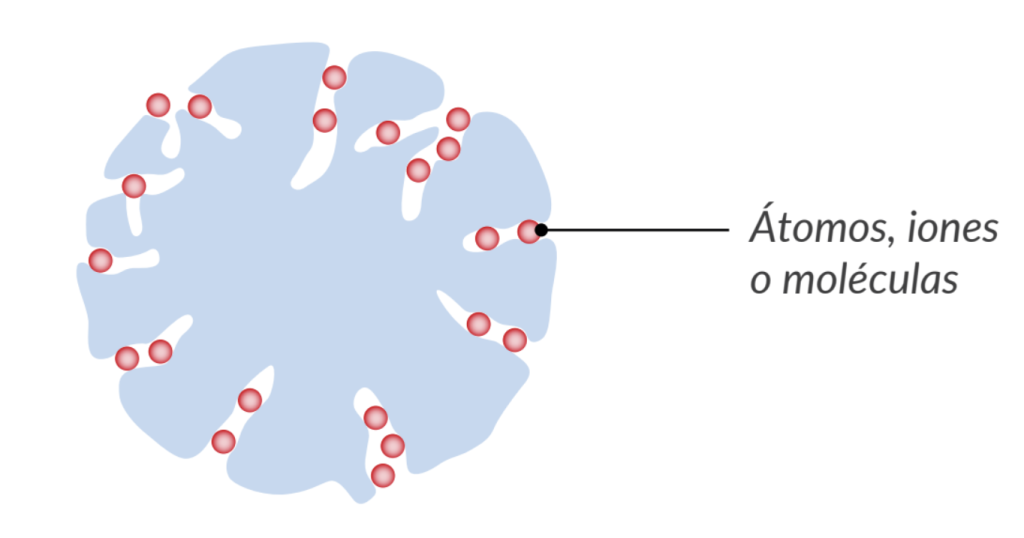

In response, a team of researchers led by Elodie Blanco and Felipe Huerta is exploring an innovative solution to improve hydrogen storage. Their approach involves filling traditional tanks with activated carbon—a material derived from carbonized waste from the forestry and agricultural industries. Activated carbon is highly porous, allowing it to adsorb large amounts of hydrogen through a process called adsorption. This method offers an efficient and cost-effective way to store hydrogen, and since activated carbon is inexpensive and widely available, it could be scaled up for large applications.

Activated carbon can attract and hold hydrogen on its large surface area, almost like a magnet. This process is known as “adsorption.”

How Activated Carbon Works?

Activated carbon can attract and trap hydrogen on its expansive surface area, similar to how a magnet attracts metal. This phenomenon, known as adsorption, allows large volumes of hydrogen to be stored efficiently. However, as hydrogen molecules are adsorbed, heat is generated within the tank. This increase in temperature and pressure makes it more challenging for the carbon to adsorb additional hydrogen molecules, which reduces the overall efficiency of the process.

Innovating for Better Performance

To tackle this issue, the researchers are developing a tank designed to dissipate the heat generated during adsorption, maintaining the carbon’s ability to store hydrogen optimally. One of the most innovative aspects of this design is the incorporation of extended surfaces, which increases the contact area between the tank and its external environment, improving heat transfer. This advancement is illustrated in the following image:

Department of Chemical Engineering and Bioprocesses

Department of Construction Engineering and Management, Department of Chemical Engineering and Bioprocesses

The mathematical model supporting this tank, alongside the prototype currently under development, is yielding promising results. Experiments have shown that a tank with activated carbon is not only more cost-effective but also more efficient than traditional pressurized tanks. By improving heat transfer within the tank, this design allows hydrogen to be stored at lower temperatures and pressures, which not only enhances efficiency but also improves safety—making it more suitable for transportation, such as by truck.

Optimizing and scaling this tank would represent a major leap forward in the global shift toward renewable energy, making green hydrogen a more competitive alternative to fossil fuels. Chile, with its abundant wind and solar energy resources, stands out as an ideal location for green hydrogen production. The country’s geographic advantages position it to harness renewable energy at scale, offering a promising foundation for large-scale green hydrogen production.

Promising Results and Future Potential

Department of Chemical Engineering and Bioprocesses

Department of Construction Engineering and Management, Department of Chemical Engineering and Bioprocesses