Department of Mechanical and Metallurgical Engineering

Portada » Solar energy storage using waste from copper extraction for industrial heat supply

Department of Mechanical and Metallurgical Engineering

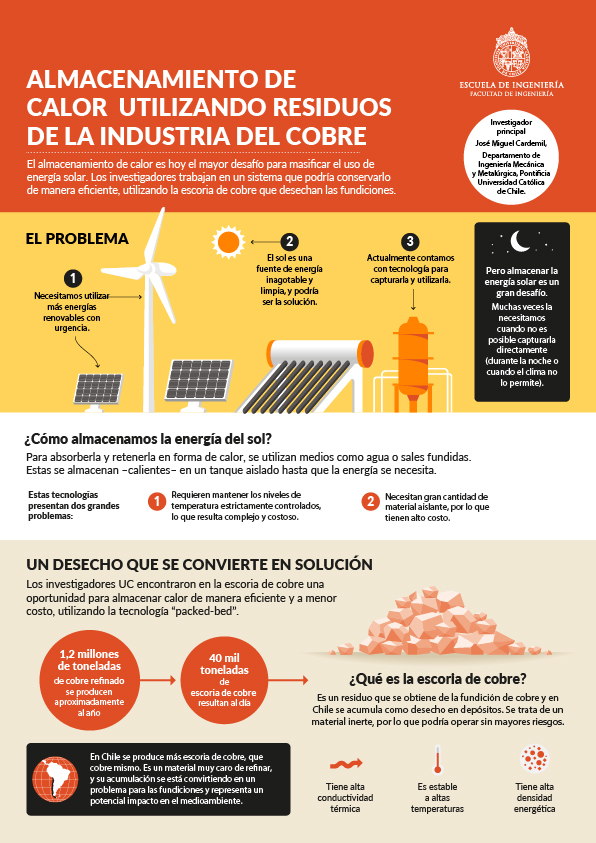

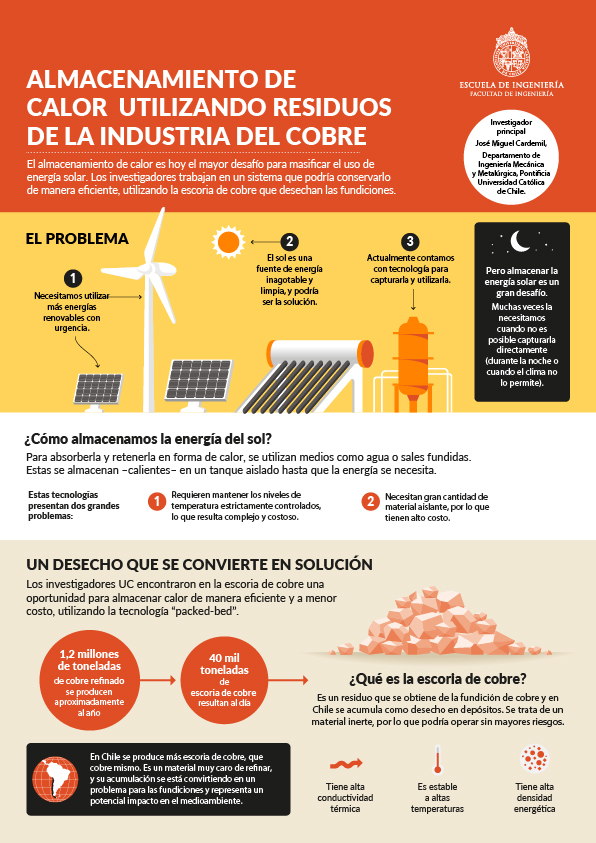

Solar energy is one clear example. Northern Chile is endowed with an enormous availability of solar radiation, with the world’s highest surface irradiance in the Atacama Desert, where the level of direct solar radiation index exceeds 3600 kWh/m2 annually (DNI). Despite this particular advantage, we have yet to develop technologies allowing us to realize its full potential. Indeed, in 2023, more than 20% of the electrical energy generated by solar plants went unused due to insufficient transmission infrastructure and/or lack of energy storage systems.

Despite this particular advantage, we have yet to develop technologies allowing us to realize its full potential. Indeed, in 2023, more than 20% of the electrical energy generated by solar plants went unused due to insufficient transmission infrastructure and/or lack of energy storage systems.

This situation usually occurs when there is a mismatch between the supply of solar power and the energy demand: radiation is received during sunshine hours with variable intensity, whereas electrical demand peaks after sunset. On the other hand, the demand for heat in most industrial settings follows a relatively constant profile 24/7. In this context, thermal storage systems may become crucial components to ensure a continuous supply of energy and provide stability to the electrical grid and heat supply for industrial processes.

To tackle this issue, Professor José Miguel Cardemil and his team are focusing their efforts on the development of innovative methods to capture, store, and utilize solar heat. Their main goal is to implement storage technologies that are more cost-effective, sustainable, and scalable compared to those traditionally available. In this quest, they studied the properties of copper slag, a byproduct of the copper smelting process. This material, highly abundant and cost-effective in Chile, possesses three properties that make it an excellent candidate for heat storage: high thermal conductivity, stability at high temperatures, and high energy density.

The copper industry in Chile generates more than 40,000 tons of copper slag per day. This waste is difficult to refine due to the associated costs, and its accumulation can generate a problem not only for the smelters but also have a negative impact on the environment.

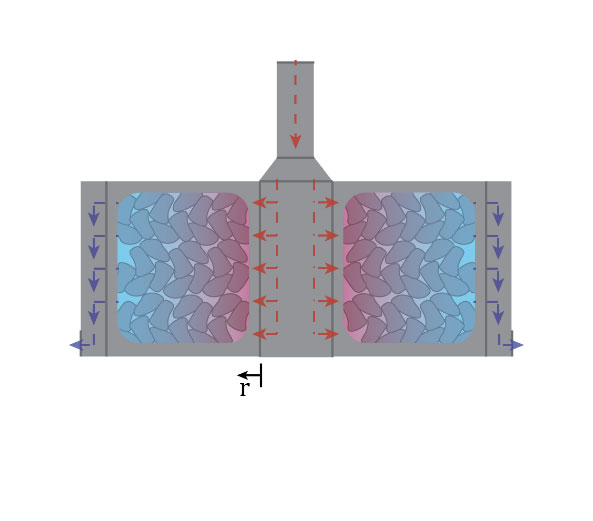

Considering the benefits of using a waste product from the copper industry and its contribution to a circular economy, the team explored the potential of copper slag as a filler material in a “packed bed”: a tipically cylindrical tank filled with solid material that allows a fluid to pass through, exchanging heat with the medium. The tank’s design distributes the flow radially, from the center of the tank to the outer layers, creating a self-insulating effect. By concentrating the higher temperature particles in the center of the tank, the outer wall of the storage is in contact with the lower temperature region of the filler material, reducing thermal losses by 70% compared to other thermal storage systems.

The system can operate using different heat transfer fluids but has been primarily tested with air, which can be heated through solar collectors or electric resistances powered by renewable energy. Thus, when hot air passes through the copper slag, it raises its temperature, storing the heat. To recover and utilize this heat, the flow is reversed by injecting low-temperature air, which is heated as it passes through the slag and can then be supplied to industrial processes.

Department of Mechanical and Metallurgical Engineering

Conceptual diagram of the packed-bed storage system illustrating the internal tank design where solar-heated air flows radially from the center to the outer walls, creating a self-insulating effect.

To study the performance of packed-beds filled with copper slag, Professor Cardemil and his team built three tanks in the laboratory and conducted tests at temperatures ranging from 50°C to 700ºC. They found that this technology allows stable operation at higher temperatures compared to other alternatives (700°C versus 565ºC for molten salts), thus making the energy conversion process more efficient. It was also shown to require a smaller storage volume, potentially reducing implementation costs, primarily due to the low commercial value of copper slag, along with the use of atmospheric air to transfer and recover stored energy.

These findings demonstrate that copper slag has a high thermal storage capacity, and all tested tank designs proved to be energy efficient. However, to further optimize their performance, the team is working on developing an air injection system that distributes heat more efficiently, combined with a control system to monitor the packed-bed operation with greater precision.

This storage method could give a valuable use to tons of industrial waste while harnessing solar energy, both through thermal collectors and the use of electrical energy discharges. This approach significantly cuts storage costs, enabling the provision of 24/7 supply of industrial heat at a competitive price. Solar energy could thus establish itself as a competitive renewable energy source in both electric and thermal markets, offering clean, secure, and dependable energy solutions.

Packed-bed storage system built by the research team. On the left the entire setup, with a more detailed view inside the cylinder filled with copper slag on the right.

Department of Mechanical and Metallurgical Engineering